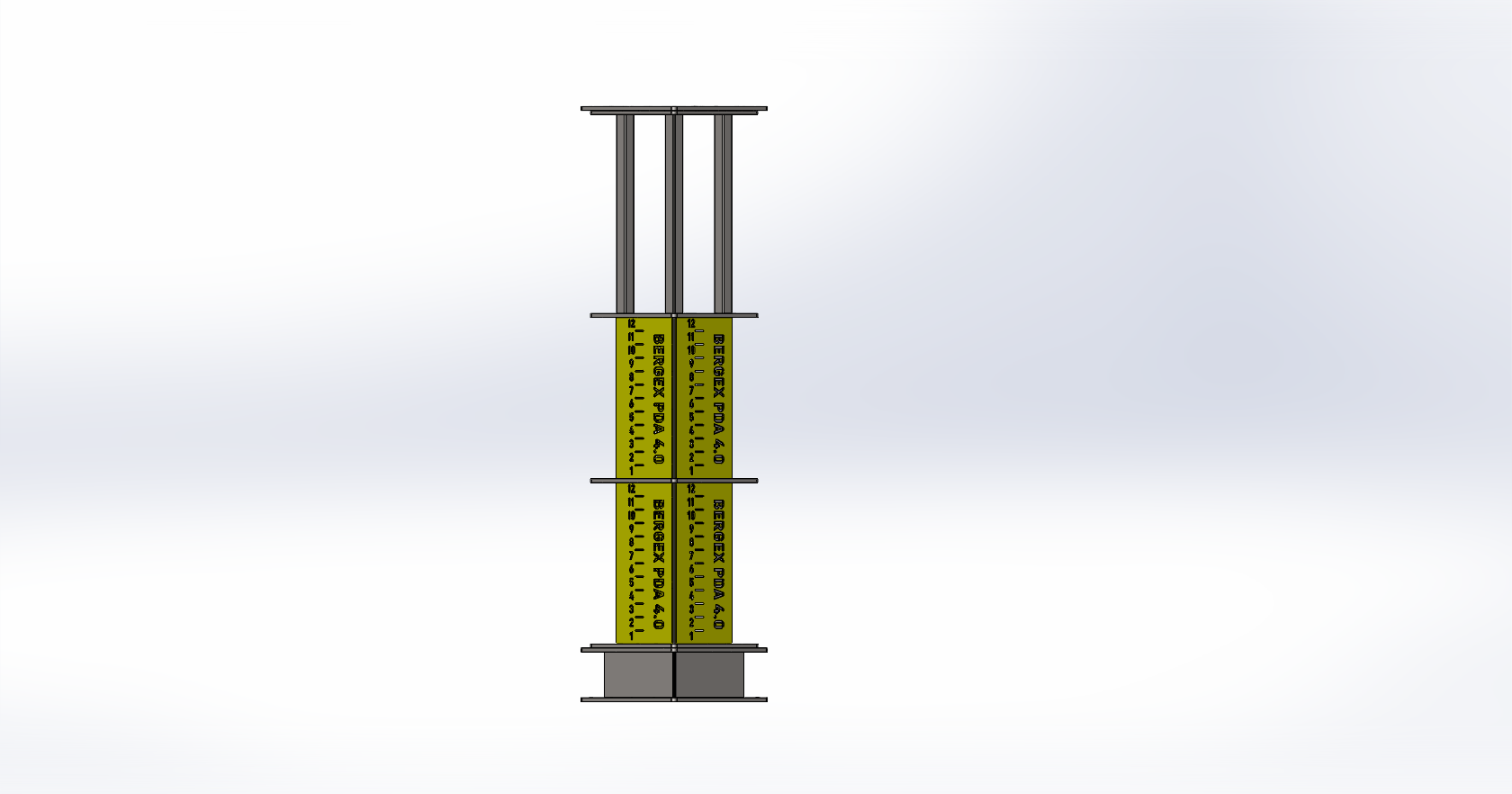

PDA 1.2

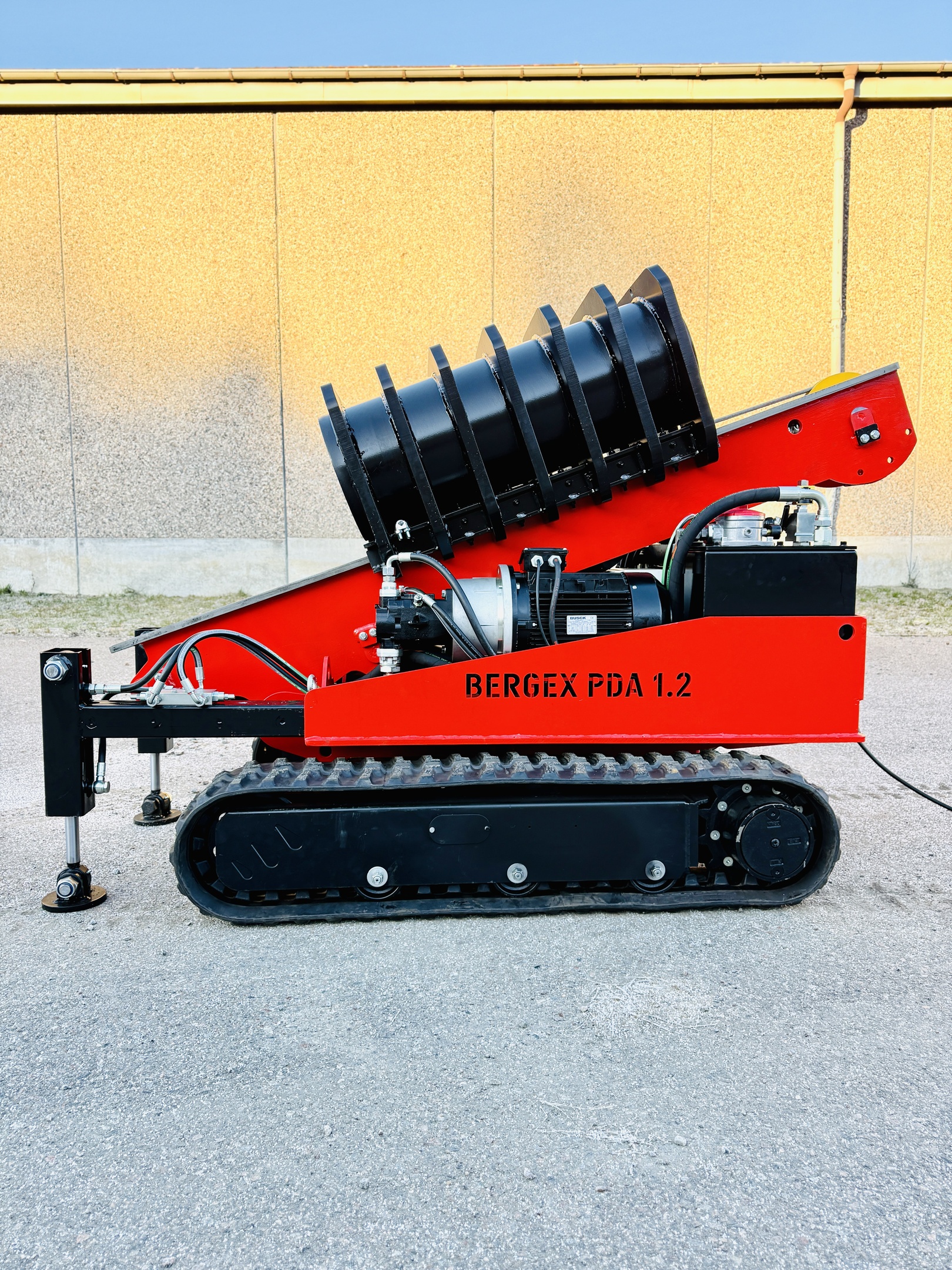

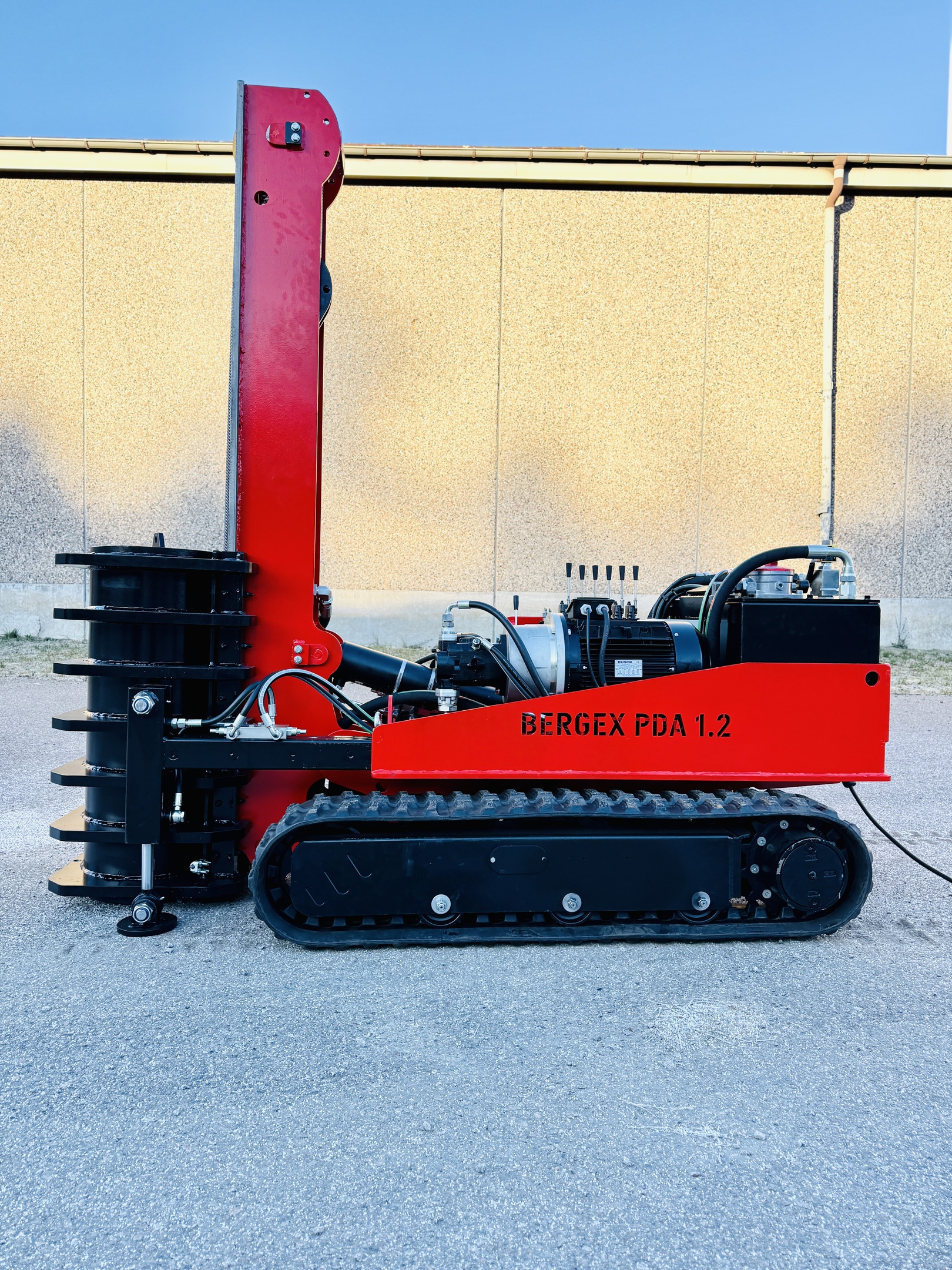

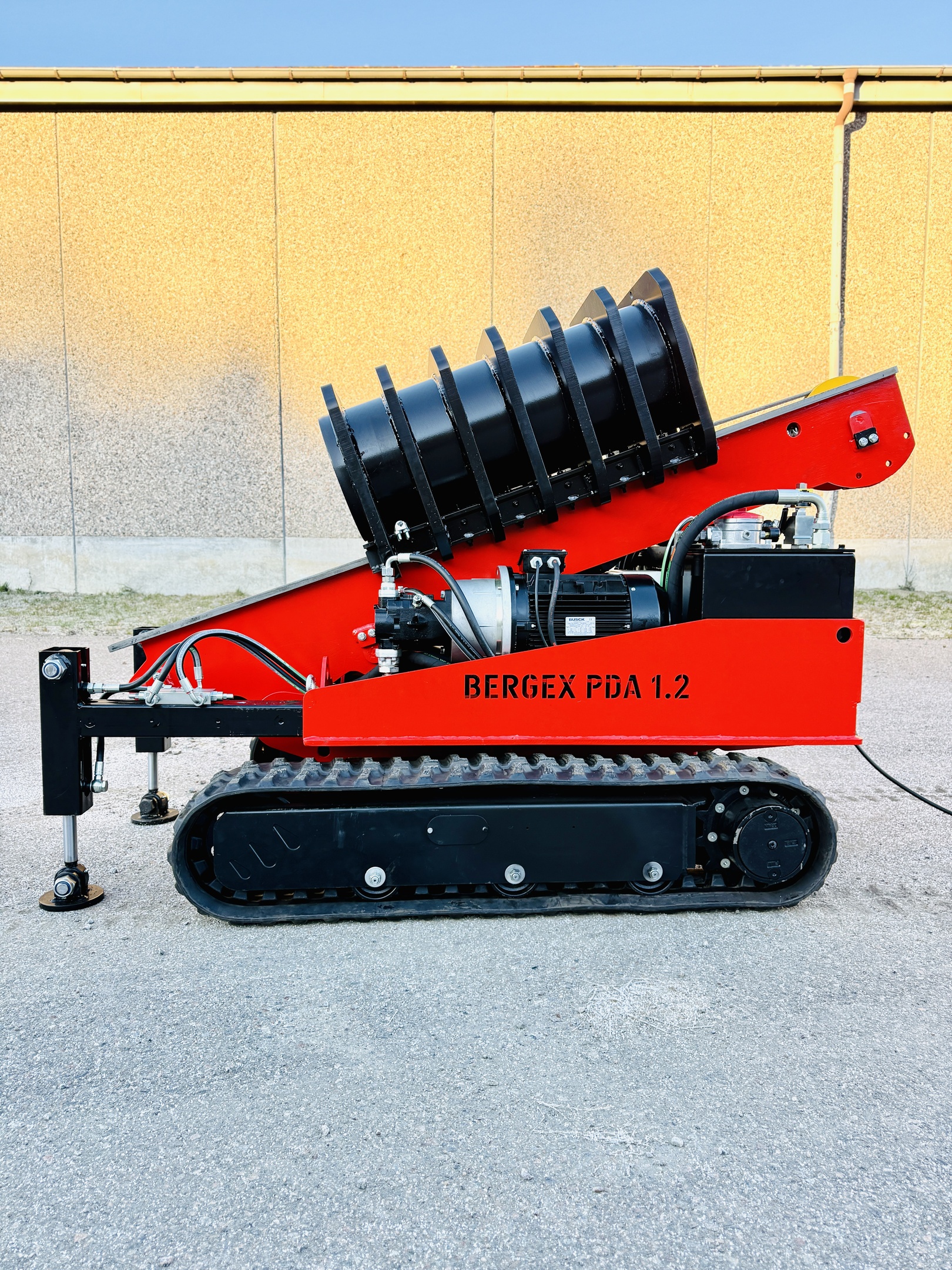

PDA Machines

PDA machines (Pile Driving Analyzer) are specialized measuring instruments used in geotechnics and pile technology to monitor, analyze, and evaluate piling work in real-time. They play a crucial role in quality control and verification of load-bearing capacity for driven piles (both sheet and concrete/steel piles).

🔧 What is a PDA Machine?

A PDA machine is an electronic device connected to sensors (accelerometers and strain gauges) mounted on the pile. It is used during driving or vibrating piles to measure:

Velocity (acceleration)

Pile Force (deformation/stress)

Energy Transfer from the Pile Hammer

Load Capacity in Soil (axial capacity)

Pile Integrity (cracks, breaks, etc.)

⚙️ How does PDA work?

Sensors are installed near the top of a pile that is to be driven into the ground.

When the hammer strikes the pile, the following are registered:Acceleration (velocity) – used to calculate the speed at the pile head.Strain (deformation) – used to calculate the force.

These signals are sent to the PDA machine, which performs an analysis based on wave theory.

The results can be analyzed with software such as CAPWAP (signal matching), to estimate:Earth resistance (static and dynamic capacity)Any failure of the pileHammer efficiency

📈 Common applications

Verification of load-bearing capacity during pile foundation

Control of installation techniques (impact rate, energy transfer)

Integrity check (cracks, breaks)

Quality control according to standards such as Eurocode or ASTM

Investigations in case of problems with bearing capacity or installation

📋 Advantages of PDA analyses

✅ Fast and portable – analyses are conducted in the field

✅ Non-destructive method

✅ Allows real-time adjustments during installation

✅ Cost-effective compared to full-scale static load tests

✅ Can be used on both prefabricated concrete piles, steel piles, and wooden piles